VENEER CUTTING METHODS

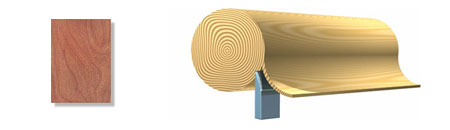

Rotary-Cut Veneer

Rotary-Cut Veneer is manufactured by advancing a rotating log against a stationary knife. Since this cut follows the log’s annual growth rings, a wide, bold grain pattern is produced. Rotary-cut veneer is a cost effective method to obtain remarkable effects from birch, maple and oak.

Plain-Sliced Veneer

Plain-Sliced Veneer is the most widely used in architectural doors. It is manufactured by advancing a half log against a stationary knife in an up-and-down movement. The resulting cut is characterized by straight grain intermixed with cathedral-like shapes. This method is moderately priced and is available for most wood species.

Quarter-Sliced Veneer

Quarter-Sliced Veneer uses the same cutting method as plain-sliced veneer, except the log is cut into quarters prior to slicing. This method cuts the annual growth rings and results in a straight grain or ribbon-striped (mahogany) appearance. Due to low yield from the log, this veneer is usually more costly.

Rift-Cut Veneer

Rift-Cut Veneer uses various species of oak. The rift, or comb-grain effect, is obtained by slicing slightly across the medullary rays. This accentuates the vertical grain and minimizes flaking. Rift-cut veneers are more expensive due to lower yield from the log.

Long sliced (also called Marunaca)

Long sliced (also called Marunaca) is made by slicing a wood beam gently through the growth rings. This method accentuates the vertical grain and minimizes flaking. This type of cut is more expensive than quartered and flat cuts.

Half round

Half round is made by cutting the block parallel to the growth rings. As this cut follows the growth rings of the tree, a sequence of pronounced large grains will form. The half round is a lower cost type of cut than the flat cut that gives a nice look with the birch, maple and oak.